Build a Transom Above a Stock Door

A decorative transom fills in the space between a stock door and the home's 9-ft. ceiling, saving the cost of a custom door.

Synopsis: In a house with tall ceilings, you could spend a lot of money on custom doors. In these situations, trim carpenter Gary Striegler likes to use stock doors and give them a custom look by building a transom above them. In this article, he explains his process for building and installing a transom in a house with a 9-ft. ceiling.

Years ago, transoms were part of the climate-control system for rooms in buildings. They operated like awning windows, letting warm air escape near the ceiling when opened. None of the transoms I build today operate, but they do let in light. And with the high cost of custom doors, transoms are a great way to give basic doors a custom look with today’s higher ceilings.

I’ve built many different types of transoms, but the one I cover here uses a paint-grade wood frame that looks a lot like the old operable transoms. It typically takes a minimum of 14 in. of space above the door jamb to build this type of transom. On this project we had 9-ft. ceilings, and the load-bearing walls had 2×10 headers snugged all the way up against the top wall plate. On non-load-bearing walls, I just have the framers header off the opening to give it the same height as a structural header. When the opening is ready, I install the door, leaving the open space above.

Build the transom jamb

The transom jamb is made out of 1×6 poplar ripped to 4-9/16 in. wide. To make the transom jamb align with the door jamb when installed, the inside measurements of the two need to be the same. I want the transom to have as much height as possible, so I leave only a minimal 1/4-in. clearance at the top.

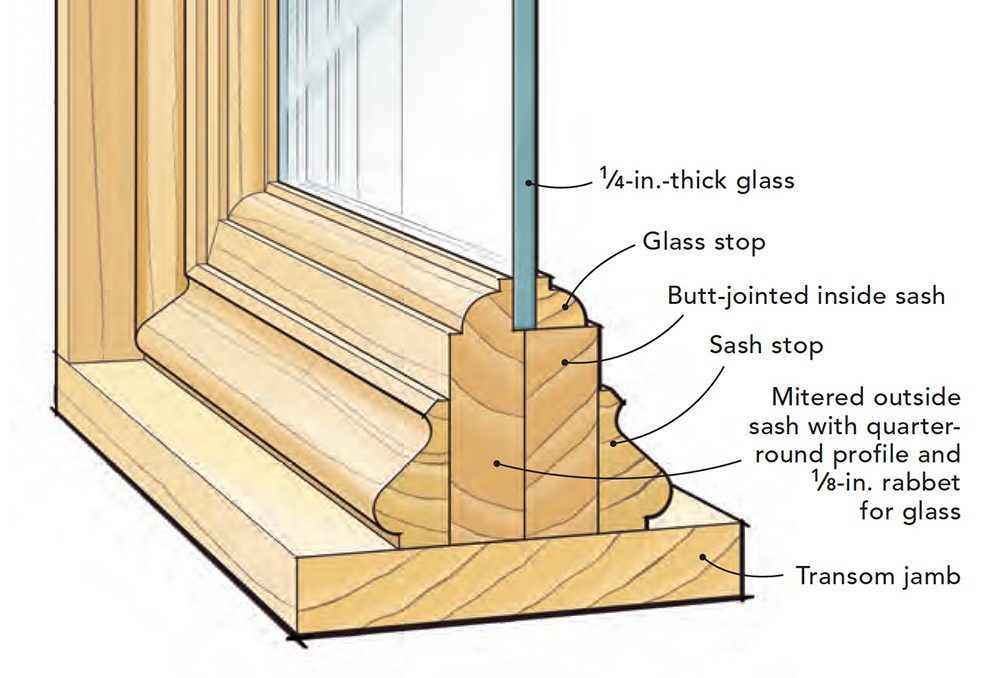

Build the transom sash

I build the transom sash out of two 3/4-in.-thick poplar frames that fit back-to-back inside the transom jamb. The first frame, which is for the outside (the most visible side) of the transom, has mitered corners. To build the frame, I rip the sash stock slightly wide, then run it through the planer to remove sawblade marks and to dial in the precise width. I also rout a decorative quarter-round profile along one edge of the stock for the money side of the sash, with a rabbet on the back side for the glass. I cut the frame pieces 1/8 in. shorter than the inside measurements of the jamb to give the sash plenty of room. Any gaps will be covered by panel molding that acts as a sash stop when the sash is installed.

For the second frame (for the less visible side), I plane the material narrower than for the first frame so that the inside edge of the frame lines up with the shoulder of the rabbet in my first frame. That leaves space for the glass (which I get through my local glass supplier) and stop. To complete the sash, I make the glass stop using the same router bit that I used on the inside edge of the first frame. The glass and stop are not permanently installed until the painting contractor is finished, so I tack each piece in place temporarily with a single headless pin. It’s important to stain or paint the frame edge that the glass sits against, plus the back edge of the glass stop so that no raw wood is visible through the glass.

Fit the sash in the jamb

It’s easiest to fit the transom sash inside the jamb and then install the unit as a whole above the door. As mentioned, I use panel molding to hide the gap between the sash and the jamb, and that molding acts as a stop for the sash. Just about any base-cap molding will work for this application. As an alternative, you can make your own stop molding with a router.

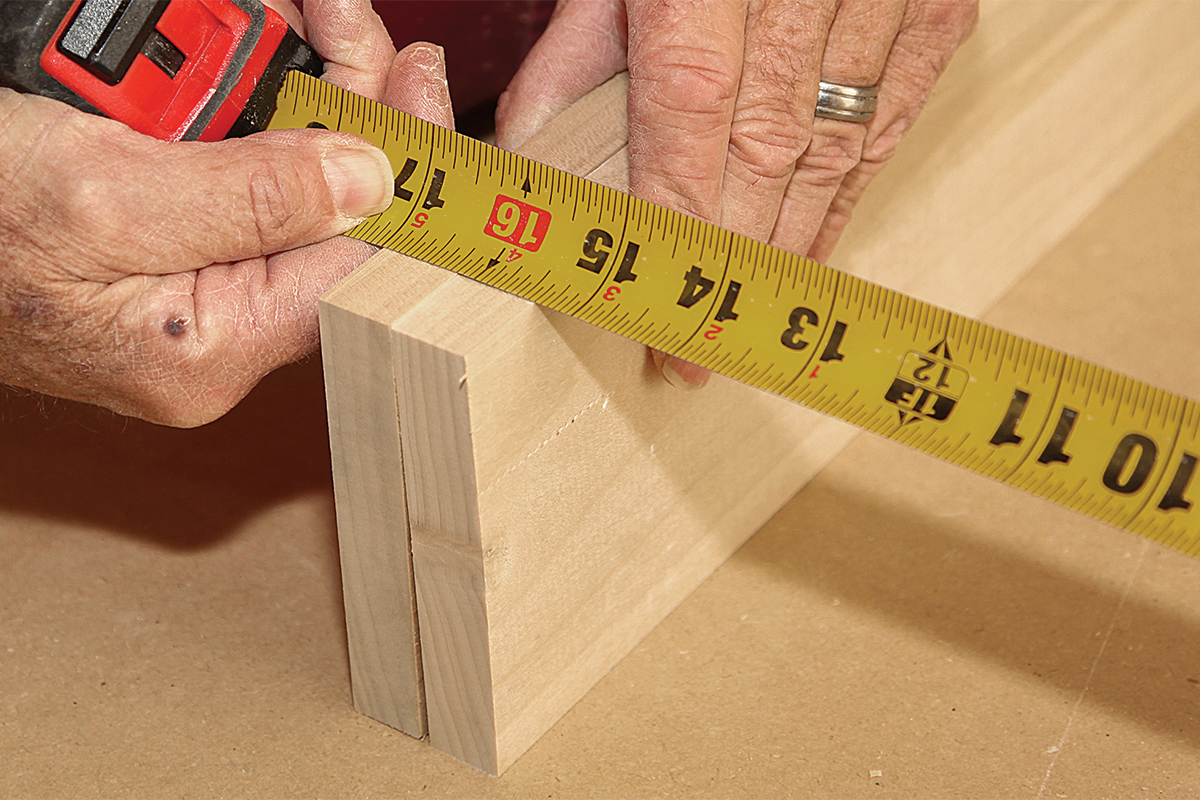

Install the transom

The most critical part of setting the transom is lining it up with the door jamb below so there’s a seamless transition to the transom jamb. I use a small square to align the side jambs and a long level to align the transom with the wall, making sure that it sits in plane with the door jamb. After the transom is installed, I finish by adding the door trim, which is just like trimming a tall door. The only catch is the horizontal mullion joint between the transom jamb and door jamb. I measure the width of the combined jambs and subtract a bit for a reveal on either side. After ripping the stock to the proper width, I plane down the thickness to match the inside edge of the door trim. I rout a simple bead along both edges of the mullion trim, cut it to length, and nail it in place to complete the installation.

Frequent Fine Homebuilding contributor Gary Striegler owns Craftsman Builders, a Fayetteville, Ark., company specializing in millwork and interior details. Photos by Roe Osborn.

From Fine Homebuilding #316

RELATED STORIES